|

| The Threaded Rod Next to a 15cm Ruler |

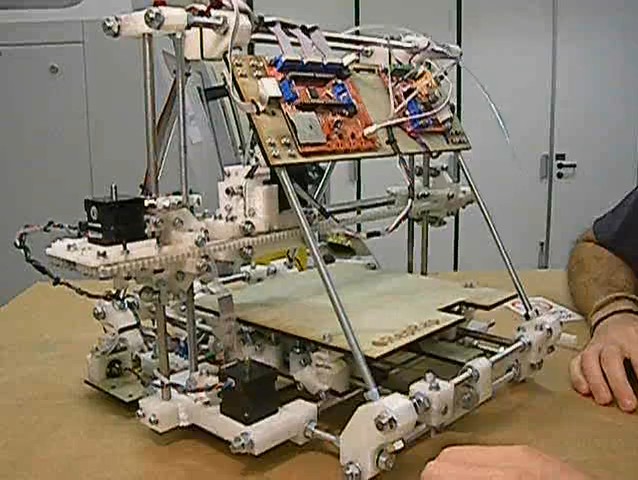

Guess what came in the

mail today?

Threaded rod, as you

could probably tell from the title and the picture. There's a total of 18 pieces, all

of various sizes that you will be able to see in the chart below. They're at

the very bottom of the new and improved chart of received items.

These rods did come from India, but they're more well traveled than you might

think. Take a look at the tracking sheet. Keep in mind that I don't live in

India so the chart goes from the bottom up. Inconvenient, I know, but better

than turning it all around.

|

Delivered - Signed for by : DAN

|

ONTARIO SERVICE AREA

|

|

With delivery courier

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Service

Area

|

|

|

Delivery attempted; recipient not

home

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

With delivery courier

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Service

Area

|

|

|

Scheduled for delivery

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

With delivery courier

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Arrived at Delivery Facility in

ONTARIO SERVICE AREA - CANADA

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Service

Area

|

|

|

Departed Facility in ONTARIO

SERVICE AREA - CANADA

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Processed at ONTARIO SERVICE AREA

- CANADA

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Clearance processing complete at

ONTARIO SERVICE AREA - CANADA

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Clearance event

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Processed for clearance at ONTARIO

SERVICE AREA - CANADA

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Arrived at Sort Facility ONTARIO

SERVICE AREA - CANADA

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Customs status updated

|

ONTARIO SERVICE AREA, ON - CANADA

|

|

Departed Facility in CINCINNATI

HUB - USA

|

CINCINNATI HUB, OH - USA

|

|

Processed at CINCINNATI HUB - USA

|

CINCINNATI HUB, OH - USA

|

|

Clearance processing complete at

CINCINNATI HUB - USA

|

CINCINNATI HUB, OH - USA

|

|

Customs status updated

|

CINCINNATI HUB, OH - USA

|

|

Arrived at Sort Facility

CINCINNATI HUB - USA

|

CINCINNATI HUB, OH - USA

|

|

Service

Area

|

|

|

Departed Facility in EAST MIDLANDS

- UK

|

EAST MIDLANDS - UK

|

|

Transferred through EAST MIDLANDS

- UK

|

EAST MIDLANDS - UK

|

|

Departed Facility in BRUSSELS -

BELGIUM

|

BRUSSELS - BELGIUM

|

|

Transferred through BRUSSELS -

BELGIUM

|

BRUSSELS - BELGIUM

|

|

Service

Area

|

|

|

Departed Facility in LEIPZIG -

GERMANY

|

LEIPZIG - GERMANY

|

|

Customs status updated

|

CINCINNATI HUB, OH - USA

|

|

Departed Facility in DELHI (NEW

DELHI) - INDIA

|

DELHI (NEW DELHI) - INDIA

|

|

Processed at DELHI (NEW DELHI) -

INDIA

|

DELHI (NEW DELHI) - INDIA

|

|

Arrived at Sort Facility DELHI

(NEW DELHI) - INDIA

|

DELHI (NEW DELHI) - INDIA

|

|

Departed Facility in MUMBAI

(BOMBAY) - INDIA

|

MUMBAI (BOMBAY) - INDIA

|

|

Processed at MUMBAI (BOMBAY) -

INDIA

|

MUMBAI (BOMBAY) - INDIA

|

|

Service

Area

|

|

|

Shipment picked up

|

MUMBAI (BOMBAY) - INDIA

|

First Mumbai, India.

Then Delhi, India. After that, the rod got it's customs papers for Cincinnati,

USA. Then off to Leipzig, Germany. That was Sunday.

On Monday, the package

arrived in Brussels, Belgium. Then the East Midlands, UK. And Monday ends.

On Tuesday, the package

finally arrives in Cincinnati where it's customs status changes to Ontario,

Canada, finally shipping to Canada Post. From there, it's in the care of Canada

Post for two days until we finally received it on Thursday.

That's a pretty well

traveled package if I do say so myself. More traveled than me, and I'm a

person.

If you take a minute and

think how much shipping and transportation that went through, as well as all of

the fuel use and staff wages, the amount of resources used to get 18 pieces of

rod, that came in a little cardboard box so skinny you could hardly see it, you

begin to realize just how much of an impact shipping a box of, say, McDonald's

frozen beef patties across Canada has. You can probably tell I'm really hungry

right now, but that's besides the point. The point is that this project takes a

massive amount of resources not because of the fact that you need a lot of

parts. The main resource cost will not come from the metal or the plastic that

is used to build said printer, but the transportation costs. All the fuel, all

the wages, all the infrastructure. Ports, boats, all built because of demand

for trade and transportation. And we're all a big part of that.

That's a valuable

lesson, is it not?